Pneumatic valves at SKEANS come in a wide variety of shapes, sizes and configurations. We are proud to say that we have some of the premier brands on offer in the industry. As the exclusive Western Canadian distributor of MAC Valves for 55 years, we can bring the best products to the market with confidence, with MAC’s historic and proven reliability. Apollo Valves have been part of the SKEANS brand for what might be 40+ years. SKEANS can offer valves in brass, bronze, carbon steel, stainless steel as well as special alloys. Butterfly Valves, backflow preventors and safety relief valves round out some of these applications. Other key brands at SKEANS include Deltrol, Mead, Pneumadyne, Flairline, Bimba, Nopak, and Camozzi.

Brands we Carry:

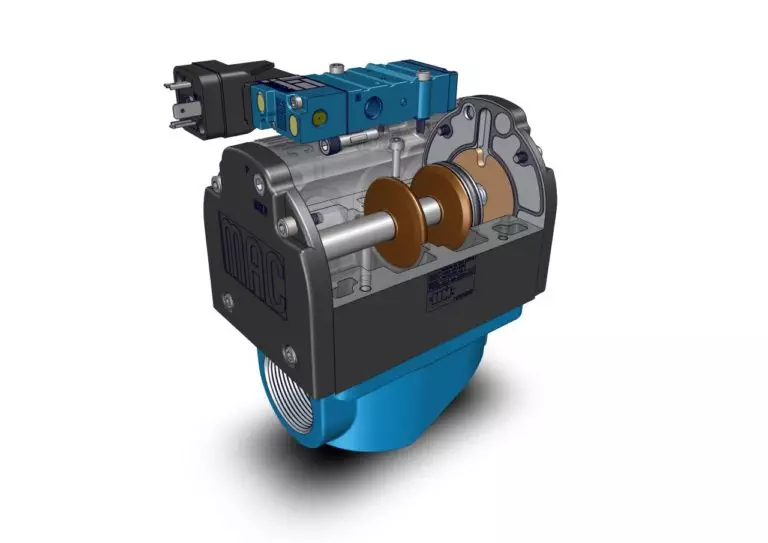

The MAC patented Pulse Valve series was developed to replace current diaphragm style technology and create a more robust and reliable valve solution in industrial Bag House applications, often referred to as a Dust Valve. MAC Pulse Valves are ideal to replace existing diaphragm technology in applications such as reverse jet bag houses and dust collectors, pneumatic conveying and bulk material handling.

The Pulse Valve can be ordered in one of two pilot configurations: The Integral Solenoid pilot combines fast, repeatable pulses with the addition of a Manual Operator, while our Remote Bleed version improves performance and reliability in Hazardous Locations. The main body of the MAC Pulse Valve utilizes bonded spool technology for superior reliability beyond existing diaphragm technology. A checked accumulator and a main spool with memory spring are used to ensure a shift back to the home position, for times when air supply may not be adequate. A line of adapter plates has also been released to replace existing diaphragm pulse valves with a direct drop-in, without disturbing existing plumbing.

It is now available in 4 size ranges:

- PV03, for ¾” – 1” applications

- PV06 for 1 ½” applications

- PV09 for 2″ – 2 ½” application

- PV12A for 2-1/2″ to 3″ application

7 Key Advantages:

- Energy Savings, Access is simpler than traditional bag house valves, less downtime with few change outs, less wasted Product, Lower Maintenance Costs, Longer filter bag life and overall ease of use

For more information click here.

MAC’s extensive line of valves approved for Hazardous Locations is distinguished by its industry leading technology and legendary reliability. Available in 2-way, 3-way and 4-way configurations, with flows up to 175Cv and having globally recognized approvals, MAC has a valve solution that will bring value to your application. The size of the Hazardous Location electrical enclosure will for some Series necessitate the use of pilot spacers. While these spacers will be included as part of the build when ordering complete valves, they will need to be ordered separately for your own conversions

100 Series – direct solenoid poppet valve, short stroke solenoid, balanced poppet powerful return spring. 2 or 3 way configurations, NO or NC or Vacuum

1/8″-1/4″ 0.18 CV – Inline, stacking, sub base manifold, non plug in

1100 Series – Mechanical operated, manual operator levers, push buttons, cams and remote air versions. 2 or 3 way configuration

1/8″ – 1/4″ 0.18 CV – Inline – sub base, manifold

200 Series – Direct solenoid poppet valve, hazardous Class I/Div B,C & D – Class II/Div E,F & G) short stroke solenoid, balanced poppet

1/8″-1/4″ 0.50 CV – Inline, Hazardous, Manifold, non plug in

31 Series – 6mm poppet valve, direct operated 3 way high flow (for it’s size) is unique to MAC, oval armature, balanced poppet

M3 0.06 CV – Inline, Manifold plug in, non plug in

32 Series – 10mm high flow, pilot operated spool, integral 4 way pilot, 3 or 4 way configurations, no pistons, minimal shift resistance, balanced design

1/8″ – 1/4″ 0.4 CV – Individual sub-base/manifold, plug in, non plug in

35 Series – direct solenoid poppet, 2 or 3 way, NC, NO, Vacuum, balanced poppet, high shifting force, fast consistent response times & long life

1/8″ 0.17 CV Inline, stacking, sub base/manifold, non plug in

These are just SOME of the small 3 – way solenoid offerings check out these links for more information and product selection

Liquid & process valves

- 2-way, 3-way, variable flow, filling and dosing valves

- Wetted and non-wetted (media-separated) solenoids

- Accurate and repeatable dosing

- Dual-diaphragm D-Flex™ Technology

- Reliable operation in extreme environments

Apollo Safety relief Valves are suitable for use with liquids such as Water, Hot water, Steam, Air & Gas. Apollo Valves are ASME certified. Check out their website for more information on the wide range of products available.

Liquid Safety Valves (apollovalves.company)

Ball and manual valves come in every shape, size and designed for every application imaginable. SKEANS stocks a plethora of Ball and manual control valves and has access to countless other options. Below are just a sampling of what we have to offer. Contact our sales team today to inquire about your valve requirements.

Selecting the right air control valve to regulate system pressure, direction of flow, and rate of flow is crucial when designing fluid power circuitry. If the pneumatic valve is too big for your application, you will be wasting air and money. If it’s too small, the actuator will not function properly.

- Pneumadyne offers a variety of porting options for plumbing convenience

- Numerous configurations for added versatility

- Flow rates range from 2.90 to 57 scfm at 125 psi

- Poppet or spool designs

- Operating pressures from 26” Hg to 150 psi

- Miniature size is ideal for limited space applications

A check valve is a type of valve that allows the flow of fluid in one direction only. It works by automatically opening when the fluid flows in the correct direction and closing when the flow reverses. This type of valve is widely used in many industries to prevent backflow and ensure that fluids or gases are flowing in the intended direction. Check valves are often used in plumbing systems to prevent water or sewage from backing up into a building. They can be found in industrial applications such as oil and gas pipelines, chemical plants, and wastewater treatment facilities. Check valves are available in a variety of sizes, materials, and designs to suit different applications. Below are just some of the Check valves available through SKEANS.

The Apollo 61 Series “Soft Seat” Check Valve offer reliable tight shut-off protection against reverse flow and corrosion resistance using proven ASTM quality materials made in the USA. Ideally suited for hydronic heating and other low flow applications. Soft seat allows more resistance to vibration and may be installed in both horizontal and vertical upward flow applications. Bubble-Tight Shut-off, ideally Suited for Gaseous Service EDPM Check Disc (61-500 Standard) Straight-Thru Flow Minimizes Pressure Loss, 1/2 psi Cracking Pressure

Deltrol offers direct acting or pilot operated cartridge style check valves suitable for hydraulic applications up to 5000 psi. Available using either ball or poppet technology, the check valve family from Deltrol provides a large variety of options to suit any hydraulic application. Our size 8 and 10 standard check valves function in 5000 psi circuits and provide flows up to 20 GPM while zero profile check valves can be installed below another cartridge valve for unique space savings

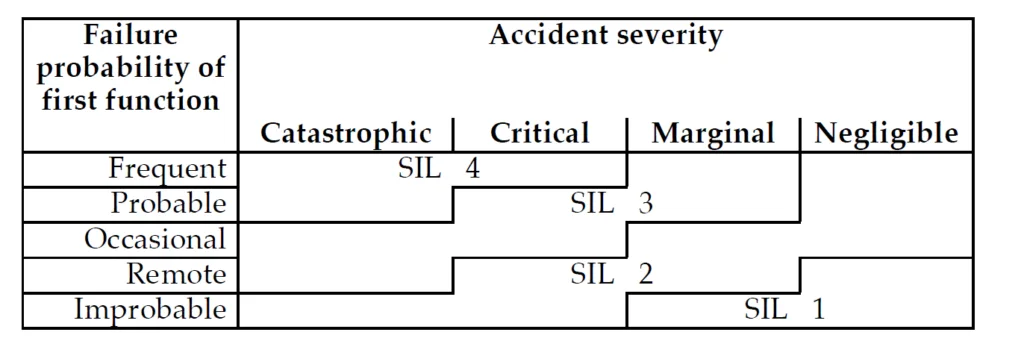

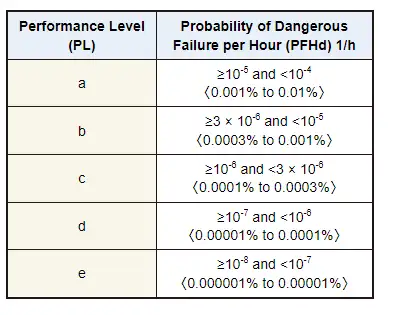

Mac Safety-Related Systems meet IEC Standards 61508 & 65511-EN ISO 13849. Also meeting Safety Integrity Level up to SIL2 and PLd and or SIL3 and PLe. Category 2 and Category 4 Standards

For more information on Safety Related systems, please complete this form

Pneumatic isolation valves are typically the first valve following the FRL components in the line supplying compressed air to pneumatic equipment. They are critical components in any safety lock-out/tagout system. Available accessories include air mufflers, pressure switches, air pressure visual indicators, and connecting hex nipples.

Intrinsically safe devices are designed for use in hazardous environments where ignition sources such as sparks or heat may be present. They have low levels of electrical and thermal energy, preventing them from creating sparks that could ignite flammable materials. They are widely used in the mining, oil and gas, chemical, and pharmaceutical industries, and undergo strict testing and certification to ensure their safety. Intrinsically safe equipment helps keep workers and assets safe, reduce the risk of accidents and maintain safe working environments.