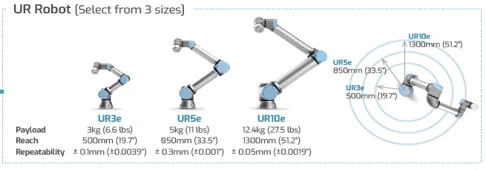

Robotic Tooling applications are significantly changing production by automating the dull, dirty, and dangerous. By 2025 it’s estimated that there will be a global shortage of 400,000 skilled and qualified workers. Collaborative Robots are helping fill some of these skilled Industry positions lacking manpower. Robots are game changers in today’s industrial world, and SKEANS is proud to be Western Canada’s Universal Robots distributor. UR Robots can be used with either Pneumatic or Electronic end of arm tooling: grippers, force torque sensors, cameras, and lights. Cable wraps and Suits further protect your investment where environment is a concern.

We also have modular equipment for your Robot Cell (or ANY application). We can support you with customizable pedestals and workstations for machine tending, bin picking and assembly that are compatible with UR Robots, and available with lockable castor, leveling castor, and floor anchor. Most of these products are also compatible with many other cobots and small to medium sized industrial robots.

Applications

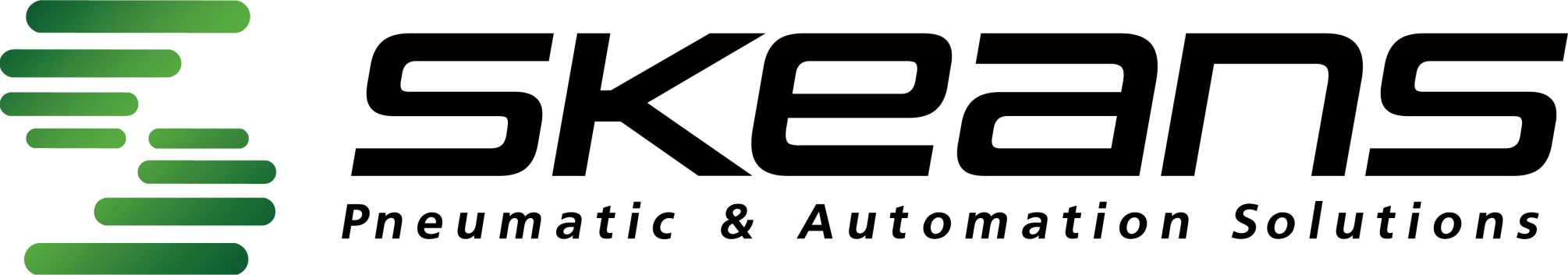

UR10e Kit for MIG, TIG welding and Plasma Cutting:

- The Challenge: A continued shortage of skilled labour

- A complete package comes fully integrated with Welder, Cart, Software and Robotic Arm

- Tailored solution to address your needs

- Easy to setup and program with user friendly software

- Backed with after sales support

- Key features: touch sense, seam tracking, shape and pattern tools and automation calibration

Universal Robots Cobots can help with a large variety of Machine Tending applications.

Keep chips flying with Universal Robot and Robotiq: kit includes

- Machine Tending Copilot software

- Robotiq MT controller

- Pneumatic panel and air nozzle kit

- Button Activator and Stack light detector

- Signle or dual Hand-E Gripper

- Foot switch Activator (if lathe application)

- Robotiq Wrist Camera (optional add-on)

- Robotiq Adjustable pedestal (optional add-on)

Once they are set, they become reference points for your operations

Use action menus and adapt the solutions to your needs for parts loading and cleaning

Machine tending copilot creates optimized movements between your key waypoints, finding the best path through the predefined flyzone and automatically avoiding collisions with the workcell

Basic and Mill edition Machine Tending Packages:

Basic Package

- Controller that allows to select and change CNC programs from the Robot

- Cycle-start CNC from the Robot

- Verify CNC program completes successfully or generates an error

- Common interface to all supported CNC controls simplifies programming

- Bi-directional communication with CNC programs via CNC macro variable read/write functions for custom programming

- Includes UR Cap to simplfy programming with Universal Robots

Mill Edition package includes the above, in addition to:

- Support for up to three CNC vices, two Robot grippers, part blow-off and pneumatic door opener

- Included CNC sub-programs allow the CNC to open/close the vises

UR Based CNC Mill automation kit:

- Cart (56” L x 32” W x 32” H)

- VersaBuilt System Controller (VSC)

- 2x MultiGrip Vises and MultiGrip Gripper

- Part and Jaw cleaner

- MultiGrip Jaws Starter kit:

2 sets of OD Jaw bases 2 sets of Top Jaws

1 set of Universal Op 1 Jaw top

UR Based CNC Lathe automation kit:

- Versa Cart (56” L x 32” W x 32” H)

- VersaBuilt System Controller (VSC)

- VSC Manages communication with CNC controller and Robot Controller, Digital I/Os and Pneumatic outputs

- Dual-Headed Gripper

- Cycle Start and Chuck Activation control

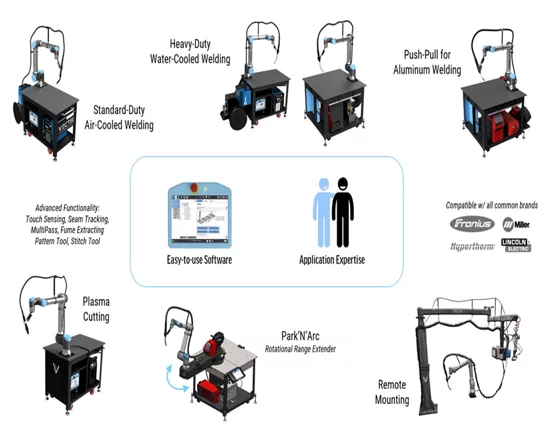

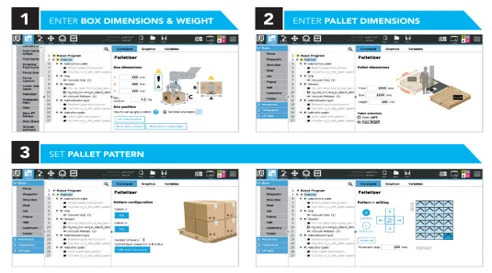

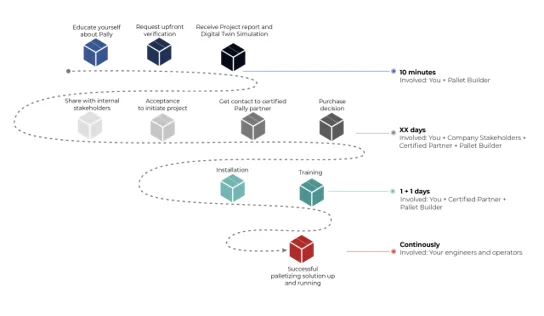

UR10e / UR20 based Palletizing kit with UR mounting column

- Comes all connected in one package ready to be deployed

- Select from standard or custom grippers

- AX Series with integrated vertical axis

- PE series with manually adjustable pedestal

- Teach Pendant and Operator Box Stand

- Setup your application in 3 easy steps

- Create the pallet pattern to automatically generate and optimize robot movements

UR10e/UR20 based Palletizing software

No-code installation and change patterns without downtime

Intelligent multi-picking to meet your palletizing requirements

Create a solution with the hardware of your choice

Unlimited height of pallets

Compatible with UR10, UR16 and UR20

Create patterns that meet your exact requirements

Compatible with PIAB Cobot Palletizing Gripper (CPT) and Ewellix lift and slide kits (7th Axis)

UR10e Sanding kit:

Comes with Air or Electric sander with mounting kits fully integrated with Universal Robots

Robotiq finishing copilot easily creates sanding paths

Various materials like Carbon Fiber, Fiberglass, Metal, Plastic, Solid Surface, Wood

Option to select from different grit sizes

Option to select different head types and sizes suitable for your application

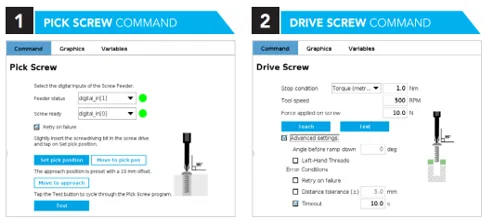

UR10e Based Screw driving Kit:

Consistent screw driving around the clock

Complete solution designed for flexible automation of screw driving tasks

So intuitive, no robotics experience is required

Program application in 2 easy steps

Supports screws from M2.5 to M5 with 4Nm torque

Automated communication between every component

Automated communication between every component

UR10e Based Glue Dispensing Kit:

- Let the Robot do what it does best; tasks which are tedious or repetitive

- Robotic material dispensing increases consistency, reduces waste, and improves product quality

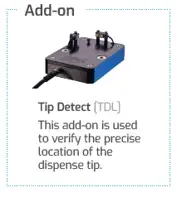

- Simply choose a dispensing head, the desired robot size, stand, and desired add-ons, and you are done

- Four (4) types of dispensing heads with tip detection add-on option

- Support for application feasibility and assessment

Bin Picking (Robot Vision):

A plug & play 3D camera for the UR

With Pickit, you can build camera supported automation applications without requiring any experience

Able to handle fast adaption and change over times

Can find parts in bins, boxes, pallets, tables etc

Minimum object size: 10 x 10 x 5 mm

UR certified solution comes with UR cap which makes part teaching and running of an application effortless

The Pickit package contains a 3D camera and Picking software ready-to-run on a dedicated industrial processor